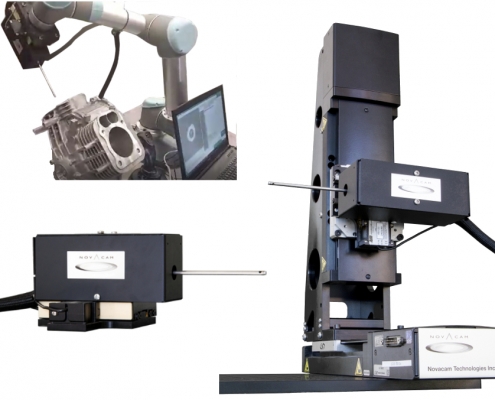

BOREINSPECTTM system

for 3D bore measurement

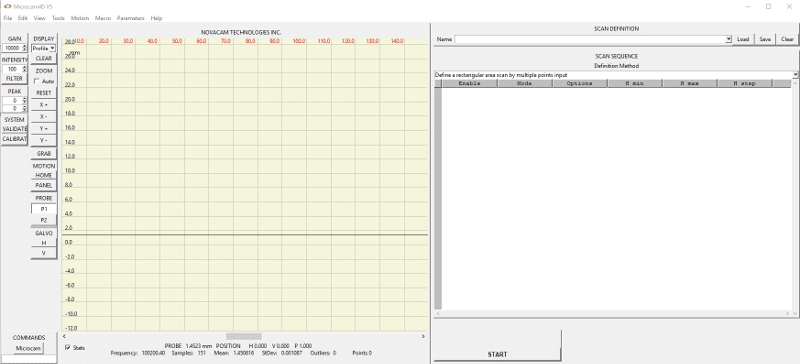

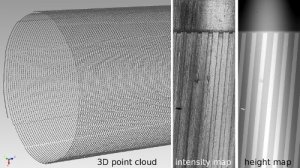

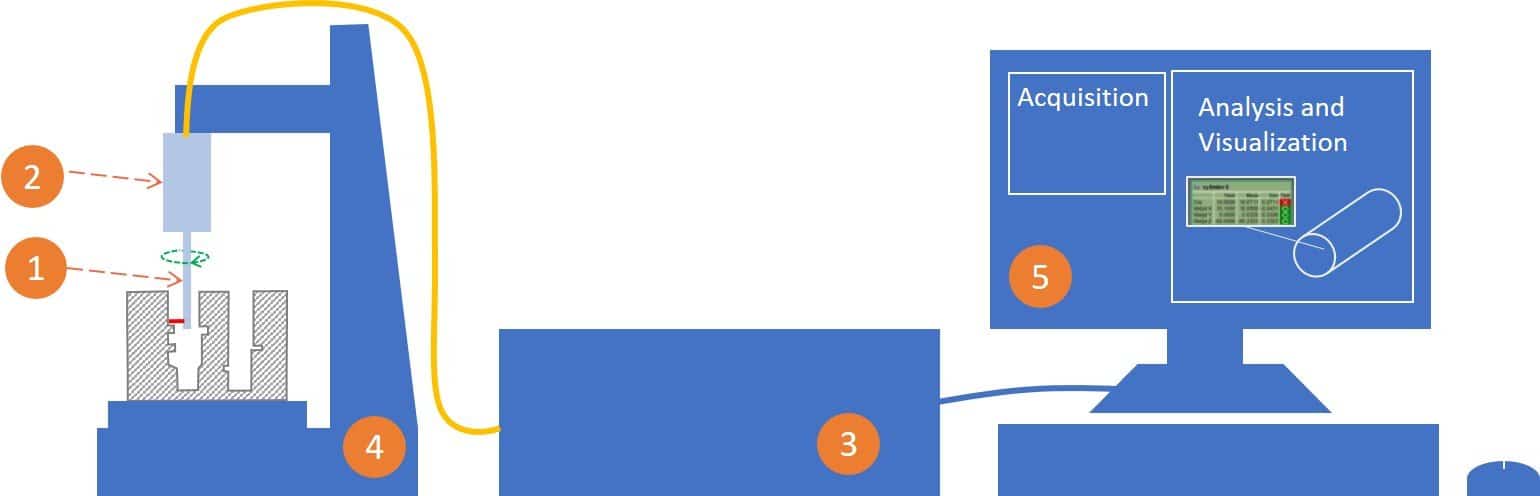

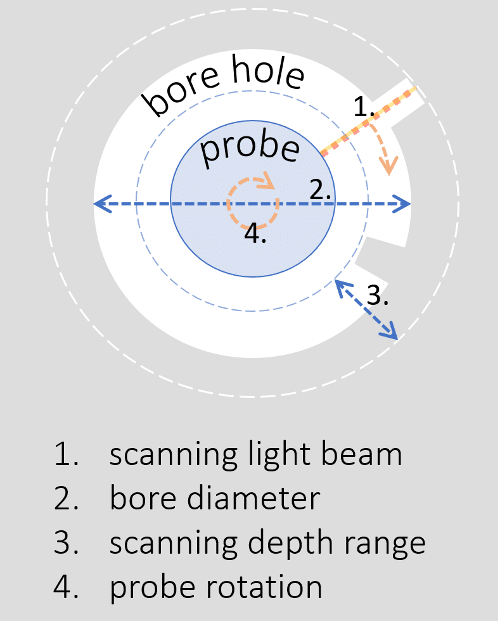

NOVACAMTM BOREINSPECTTM system is a modular, non-contact optical bore measurement system that provides micron-precision 3D measurements of bore interiors and other hard-to-reach spaces. Its rotational scanner probe easily enters tight spaces to acquire their complete inside geometry at high speed. The BOREINSPECT system:

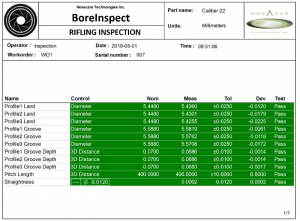

- Measures inside diameter (ID) features such as undercuts, chamfers, threads, rifling, O-ring grooves, splines, lands, and edge breaks

- Enables fully configurable automated bore measurement

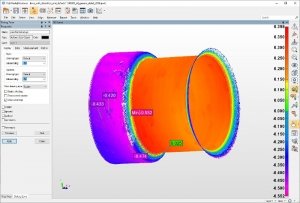

- Produces 3D point cloud data for calculating GD&T parameters

- Can measure dimensional or surface defects such as porosities, cracks, burrs, or scratches

- Can measure roughness as well as thickness of semi-transparent coatings

BOREINSPECT system in action

Valve body bores – automated 3D bore measurement (automotive)

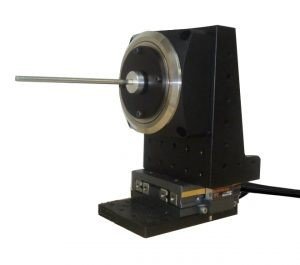

Video content: RS2, a non-contact rotational scanner and a key component of the BOREINSPECT bore measurement system, measures the 3D inner diameter of several valve body bores as part of a fully automated bore inspection.

Benefits: Fully automated 3D bore measurement, interactive 3D analysis of valve bores, measurements of distance, absolute position, cylindricity, surface/dimensional defects, roughness, geometric tolerances of internal features, dimensional deviations, and more

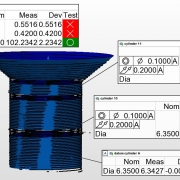

Airfoil 3D inspection (aerospace)

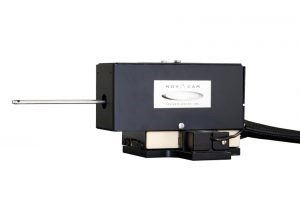

Video content: MICROCAM-3D airfoil scanner (BOREINSPECT bore measurement system) delivers micron-precision 3D optical measurements of hard-to-reach places.

Benefits: fully automated inspection of complete component geometry, airfoil trailing and leading edge, 3D modeling, micron-precision defect detection, dimensional deviations, geometric tolerances, measurement of distances.

Turbine blade – high-speed 3D metrology (aerospace)

Video content: RS2, a non-contact rotational scanner and a key component of the BOREINSPECT bore measurement system, enters the complex geometrical structures of turbine blades to completely acquire their dimensional geometry down to the micron.

Benefits: fully configurable automated scanning sequences, detection of surface or dimensional defects, characterization of EDM slots and air holes (control of fan-out angle, etc.),tolerance analysis, dimensional deviations, geometric tolerances, datum alignment capability, and more.

Bore ID chatter measurement (automotive)

Video content: Demo of a non-contact chatter gauge built by an integrator using RS2 rotational scanner (part of NOVACAM BOREINSPECT bore measurement system), NOVACAM Chatter Analysis Software, and a robotic arm. This temporary automated gauge was used to measure the chatter in 16,000 turbo shafts over 4 weeks while the client was troubleshooting a faulty manufacture line.

Inspection achievements: Fully automated bore measurement and chatter analysis, 45 second inspection cycle time, 65% of parts salvaged from a faulty manufacture line, downtime of a major automotive production line avoided.

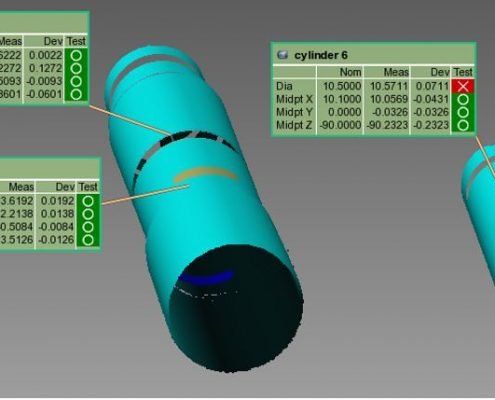

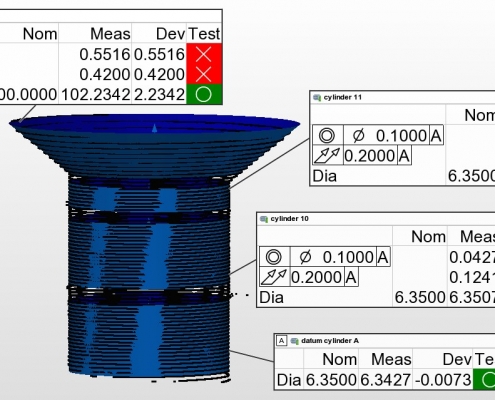

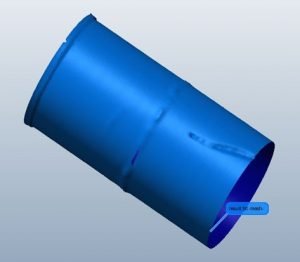

Cylinder bore measurement

Video content: BOREINSPECT non-contact bore measurement system measures a cylinder bore, providing micron-precision 3D measurements of the bore interior.

System benefits: Fully automated cylinder bore measurement, 3D measurements of GD&T parameters, chatter, roughness, and defects with one single probe. Configuration with 18 mm diameter rotational probe is ideal for 5 to 15 cm (2″ to 6″) diameter bores such as engine cylinders, actuator cylinders, etc.

Note: If a tube/cylinder bore you need to measure also needs to be measured on the outside, this can be achieved either by mounting the BOREINSPECT system rotational scanner on a gantry or by using NOVACAM TUBEINSPECT system, which measures both the ID and OD of tubes mounted on a motorized spinning fixture.

Related links

See related measurement applications:

Contact us or request free sample analysis to see if the BOREINSPECT system is suitable for your bore measurement application