Hard-to-reach spaces

Non-contact measurements in hard-to-reach spaces

NOVACAMTM 3D metrology systems facilitate surface inspection and 3D metrology inside hard-to-reach spaces across industries.

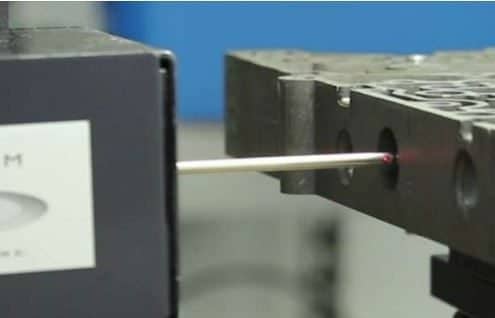

Small fiber-based non-contact probes reach inside to measure:

- Interiors of tubes, bores, barrels, and various small-aperture cylinders

- Interiors of high-precision parts made by casting, high-precision drilling, deep gun drilling, injection molding, 3D printing

- Inside surfaces of drilled rivet holes, fir-tree bases, blisks (bladed disks in the aerospace industry)

- Inside engine blocks, through-holes of connecting rods, camshafts (automotive industry)

…with micron precision and at high speeds, acquiring 2,100 to 100,000 of 3D points per second.

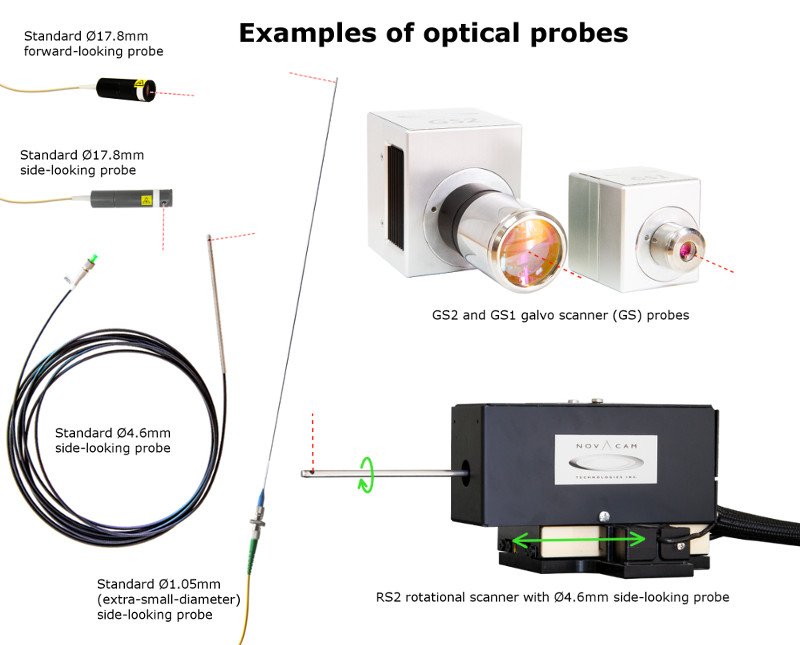

Novacam offers probes in a range of lengths and diameter sizes (as small as 0.5 mm). Probes are either side-looking or front-looking and are typically used in concert with a suitable scanning mechanism. Rotational probes are also available.

Advantages of measuring with fiber-based probes

NOVACAM systems are modular and fiber based, meaning that the scanning optical probes are connected to the system interferometer with an optical fiber that can be several meters long. Thanks to the unique combination of Low-coherence Interferometry technology and fiber-based design, the systems offer significant advantages to our clients. These advantages include:

- Configuration versatility for both in-process and benchtop inspection

- Support for automation

- Ability to acquire long profiles

- Ability to measure inside small-diameter tubes, bores, etc. See inspection in hard-to-reach spaces

- Ability to measure surfaces with steps, grooves, channels, holes, and other high-aspect-ratio features

- Ability to scan surfaces that are reflective or nonreflective, smooth or rough, stationary or moving

- Ability to measure GD&T even in extreme temperatures or in radiation. See inspection in hostile environments.

See a more complete list of advantages of our fiber-based LCI systems.

Examples of 3-D metrology applications in hard-to-reach spaces

NOVACAM systems measure hard-to-reach spaces in many sectors including aerospace, automotive, defence, medical instrumentation, energy, and electronics. Here are some examples.

Defence (firearms) sector

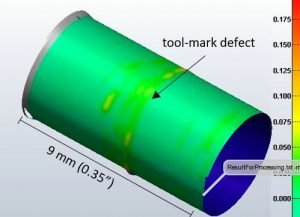

Application: rifle barrel ID inspection (ID≈5.6 mm, length≈46 cm)

Metrology system: TUBEINSPECTTM system

How it works: small-diameter probe is advanced into the rotated tube, acquiring the ID surface as a very dense spiral of 3D point measurements

Bonus system aspect: with this same system, both the inside and outside diameters of a tube can be acquired

Automotive sector

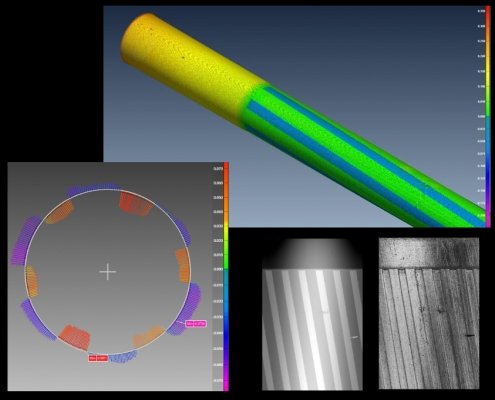

Application: automotive valve body bores

Metrology system: BOREINSPECTTM system

How it works: small-diameter rotational scanning (RS) probe is lowered into a stationary bore, acquiring the ID surface as a very dense spiral of 3D point measurements

Benefit: Easy programming of measurement sequences

Related links

Download application note “Inspecting Hard-to-Reach Surfaces with NOVACAM Non-Contact 3D Metrology Systems “ [4 pages, PDF, 1.2 MB] for more details on 3D metrology in hard-to-reach spaces

See related applications:

See related products

Contact us or request free sample analysis to see if NOVACAM 3D metrology systems are suitable for your application