Tube ID and OD measurement

Measuring System: NOVACAMTM TUBEINSPECTTM system

Keywords: tubes, cylinders, barrels, inside diameter (ID), outside diameter (OD), O-ring grooves, threads, splines, undercuts, cross-holes

Inspection requirements in high-precision industries

The inner and outer surface topography of manufactured tubes greatly affects their intended functional performance. For this reason, tubes in high-precision sectors (automotive, aerospace, medical instrumentation, etc.) must adhere to strict specifications and tolerances.

3D measurement with TUBEINSPECT system

NOVACAMTM TUBEINSPECTTM system is a modular non-contact 3D metrology system that greatly speeds up the task of high-precision tube measurement and facilitates automation. The system uses a small-diameter optical probe to enter the interiors of tubes, acquiring their inner 3D topography:

- With micron precision and

- At high speeds: up to 100,000 of 3D points per second

To measure a tube ID surface, the tube is rotated on a rotational stage while the system optical side-looking probe advances inside, acquiring the surface as a dense spiral of 3D points. Scan paths that are linear or circumferential are of course also possible. The TUBEINSPECT system may also be used to measure the tube exterior, with the same optical probe scanning the outside of the rotating tube.

Watch the TUBEINSPECT system action

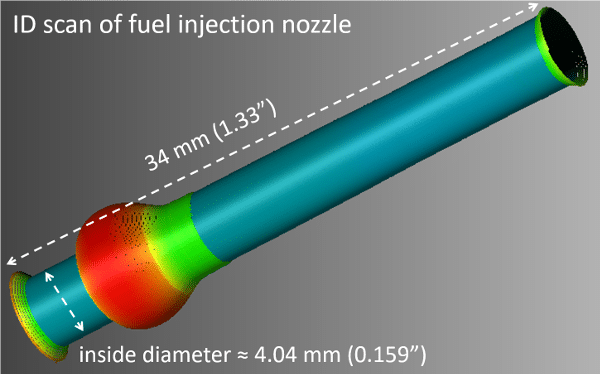

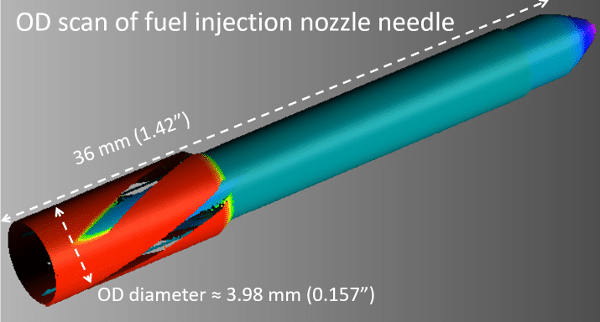

Example 1: Fuel injection nozzle and needle

The inner suface of a Bosch fuel injection nozzle and the outer surface of the matching nozzle needle were both acquired. Micron-precision measurements of such surfaces can serve as a basis of calculations to determine whether the two machined surfaces meet as required.

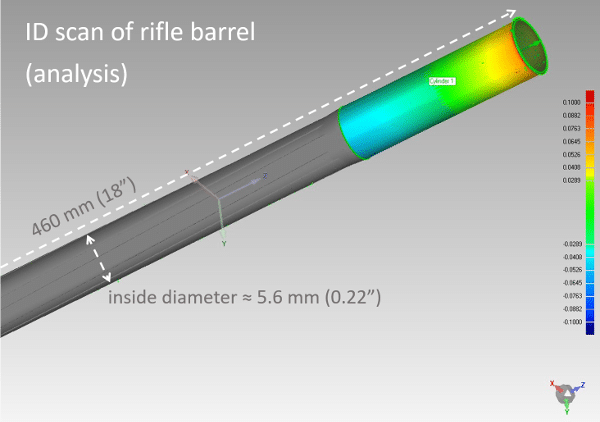

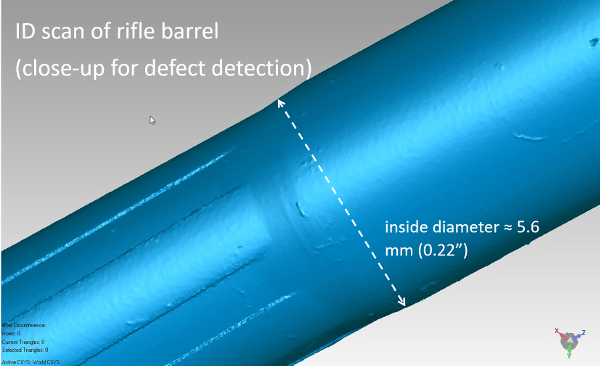

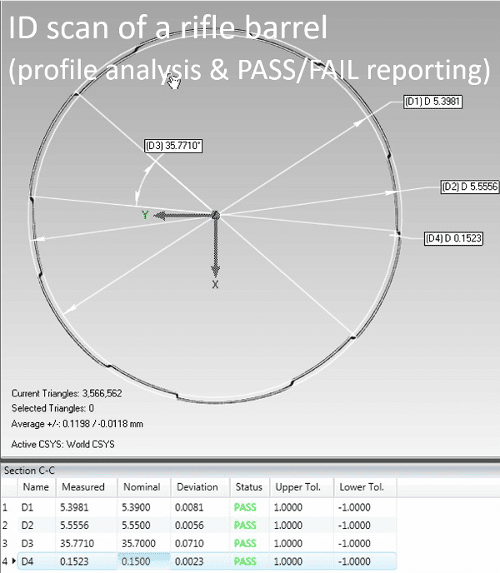

Example 2: Rifle barrel measurements – reaching in deep

The ID of an 18″ 0.22 caliber rifle barrel (length≈46 cm, diameter≈5.6 mm) was measured. Multiple geometrical dimensioning and testing (GD&T) parameters were calculated to ensure compliance to QA/QC requirements.

What can be measured

From the 3D data, clients obtain measurements of:

- Inside and outside dimensional parameters (GD&T): diameter, straightness, cylindricity, concentricity, ovality, taper, runout

- Dimensions of inner features, such as steps, splines, threads, chambers, cross-holes, and O-ring grooves

- Distortion due to chatter (lobing)

- Defects

- ID or OD surface roughness – whether roughness from straight profiles or round profiles of the ID/OD

- Thickness, such as thickness of semi-transparent coatings.

In-process or in-lab measurement

With the TUBEINSPECT system, ID/OD surface acquisition and the subsequent 3D geometry analysis, roughness measurement, and defect detection are easily automated and carried out right on the shop or manufacturing plant floor, bringing high-precision manufacturers significant savings.

-

- Automation is supported by system capabilities such as datum alignment, automated pass/fail reporting, and exportable reports

- Tube ID/OD data may be evaluated with respect to user-defined criteria (GD&T, inner feature specifications, roughness, chatter, and defect inspection), or compared to a reference CAD model.

- For in-lab inspection, accompanying GD&T metrology software (InnovMetric PolyWorks InspectorTM ) on the system PC enables full viewing and analysis of the acquired point cloud as a 3D interactive map. Views such as deviation maps provide key insight into bore machining processes.

Modular & fiber-based design for extra versatility

The TUBEINSPECT system is based on low-coherence interferometry technology. It is a modular and fiber-based optical system; its non-contact optical probe is connected to the signal-processing interferometer with an optical fiber that can be several meters long. As such, the probe is easily integrated as a 3D vision component in automated or semi-automated systems right on the plant floor. See a more complete list of advantages of NOVACAM fiber-based LCI systems.

Related links

Download application note “Measuring Tube ID & OD” [4 pages, PDF, 1 MB] for more details on this application

Contact us or request free sample analysis to see if the TUBEINSPECT system is suitable for your application