Novacam metrology videos

The videos below present just a few of the many applications of our technology. We encourage you to also visit our Youtube channel to view these and additional videos.

Cylinder measurement

Duration: 01:21

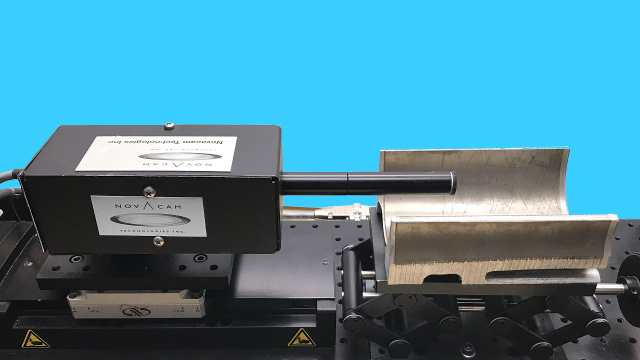

See how NOVACAMTM BOREINSPECTTM system measures a cylinder bore in a non-contact automated manner, providing micron-precision 3D measurements of the interior. Configuration with 18 mm diameter rotational probe is ideal for 5 to 15 cm (2″ to 6″) diameter bores such as engine cylinders, actuator cylinders, etc.

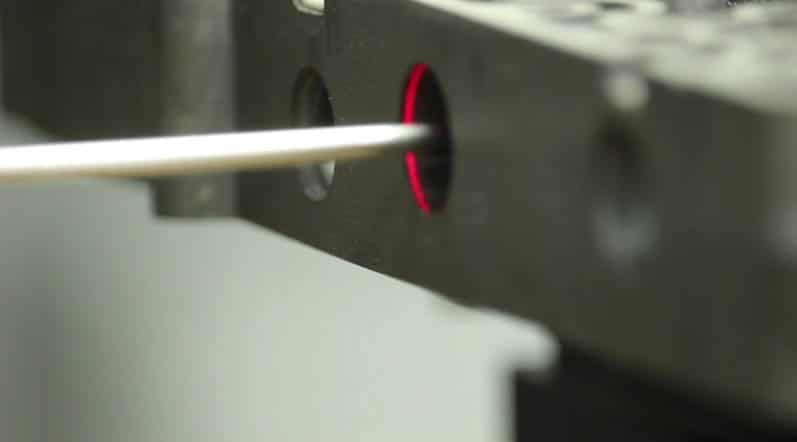

Chatter measurement

Duration: 02:15

See a non-contact chatter gauge built by an integrator using NOVACAM RS2 rotational scanner, NOVACAM Chatter Analysis Software, and a robotic arm. This temporary automated gauge was used to measure the chatter in 16,000 turbo shafts over 4 weeks while the client was troubleshooting a faulty manufacture line.

Flatness measurement

Duration: 02:00

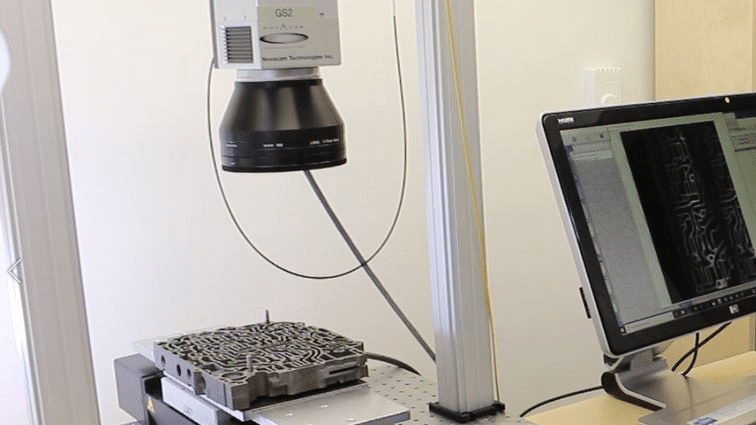

Learn how, inspecting with a galvo (raster) scanner, the NOVACAMTM SURFACEINSPECTTM system acquires a mating surface of a valve body and calculates its flatness parameters.

Edge radius measurement

Duration: 01:53

See how NOVACAMTM OPTICAL 3D PROFILOMETERTM system, equipped with with a non-contact fiber-based optical galvo scanner, characterizes tool edges in 3D and with micron-precision.

Airfoil measurement

Duration: 01:43

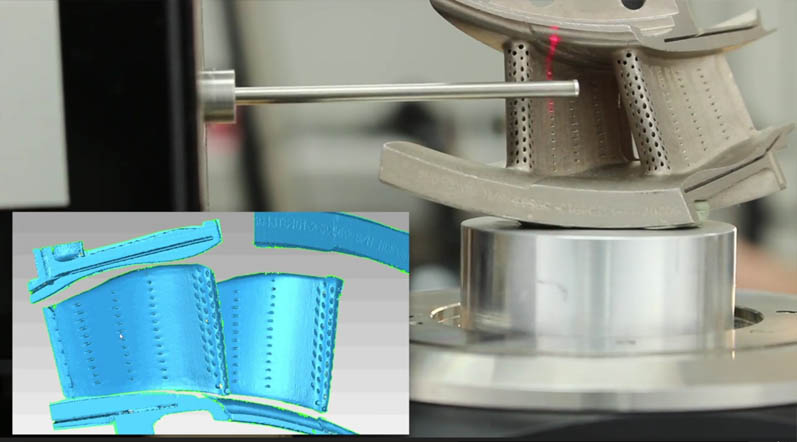

Watch how MICROCAMTM-3D airfoil scanner, NOVACAM non-contact CMMTM system delivers micron-precision 3D optical measurements of hard-to-reach places.

Turbine blade inspection

Duration: 01:51

See how NOVACAM RS2 rotational scanner acquires turbine blades with its spinning non-contact optical probe. The RS advances the spinning probe into the complex geometrical structures of turbine blades to acquire their dimensional geometry down to the micron.

Valve-body bore ID measurement

Duration: 02:02

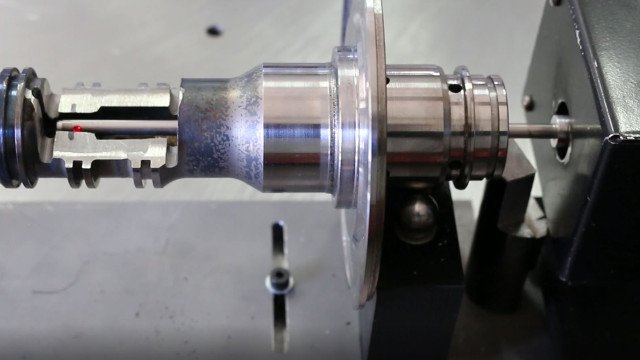

Watch a demonstration of a fully-automated digital inspection of valve body bores, where NOVACAMTM BOREINSPECTTM system uses a non-contact rotational scanner, spins and advances a small-diameter optical probe to measure the inside diameters (IDs) of these bores – down to the micron.

3D Tube ID measurement

Duration: 01:51

Learn how MICROCAM-3D tube ID scanner (NOVACAMTM TUBEINSPECTTM non-contact 3D metrology system) provides micron-precision 3D characterization of tube interiors.

Related links

Contact us – we’ll be happy to discuss your metrology needs.

Request free sample analysis to see if our 3D metrology systems are suitable for your application.

Thanks to https://neurobox.ca/ for creating many of our videos