Cooling holes inspection

Measuring System: NOVACAMTM EDGEINSPECTTM system

Keywords: aerospace industry, energy industry, turbine blades, gas combustion engines

Function and characterization of cooling holes

To help avoid heat-related failure of combustion engines, multiple small cooling holes are drilled into hollow turbine blades to discharge cooling air from the blade interior onto its surface. Cooling hole geometries have grown more complex over time to improve their functional effectiveness.

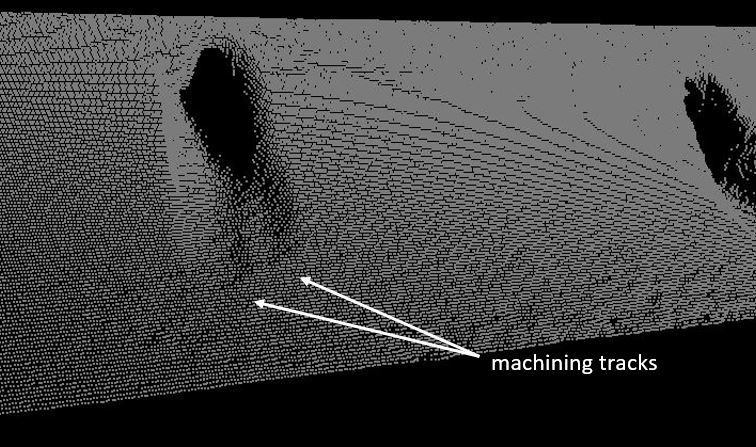

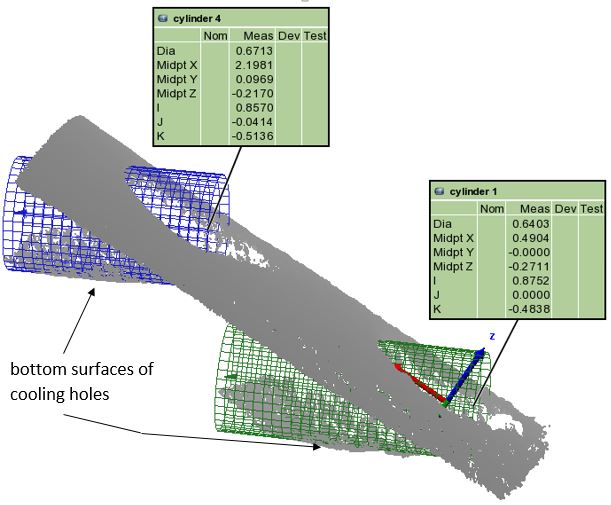

NOVACAMTM EDGEINSPECTTM system provides advanced capabilities in cooling holes inspection. This non-contact inspection system acquires high-precision 3D topography of surfaces at high speed (2,100 to 100,000 3D points per second). In a single pass over a turbine blade, the system scanner acquires a very dense 3D point cloud of the surface, enabling the characterization of:

- The shape of the diffuser opening

- A portion of the cooling hole inner diameter (ID) (which can be further extended by varying the scanning angle)

- The geometrical center of the through hole

- The inclination angle of the through hole

- The profile, waviness, and roughness of the acquired bottom surface of the cooling hole

- Dimensional variability of each hole with respect to a CAD model.

Versatile installation with a fiber-based LCI system

The EDGEINSPECT system is based on low-coherence interferometry technology. It is also a modular and fiber-based optical system; its galvo scanner probe is connected to the system signal-processing interferometer with an optical fiber that can be several meters long. As such, the galvo scanner is easily integrated with a robot arm or as a 3D vision component in automated or semi-automated systems on the plant floor.

See a more complete list of advantages of NOVACAM fiber-based LCI systems.

Inspecting cooling holes in tight spaces

Unlike microscope-like instruments, the EDGEINSPECT system can also be configured to measure surfaces in hard-to-reach spaces. While the standard galvo scanner that comes with the EDGEINSPECT system is the fastest scanning option, a small-diameter rotational scanner can also be added or substituted to acquire cooling holes in tight space such as, for example, on the inner surfaces of stator blades.

- Watch related video: Turbine blade inspection (00:02:30)

Related links

Download application note “Cooling Holes Inspection” [4 pages, PDF, 1 MB] for more details on this application

Check out related applications:

Contact us or request free sample analysis to see if EDGEINSPECT system is suitable for your cooling holes inspection process